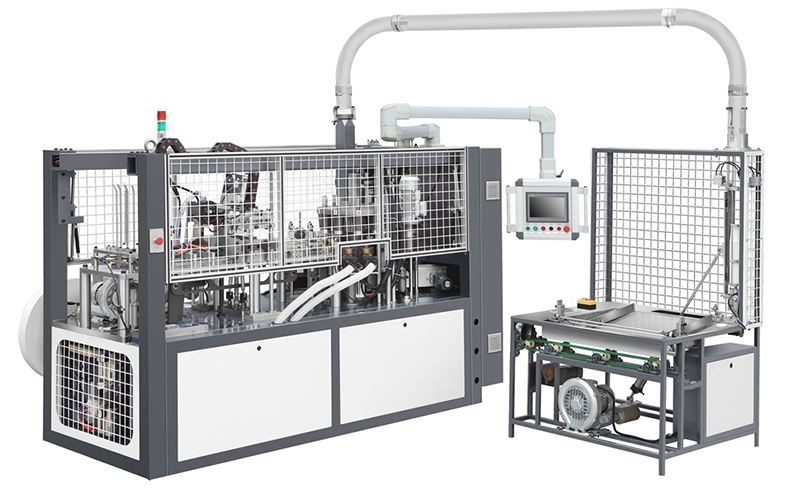

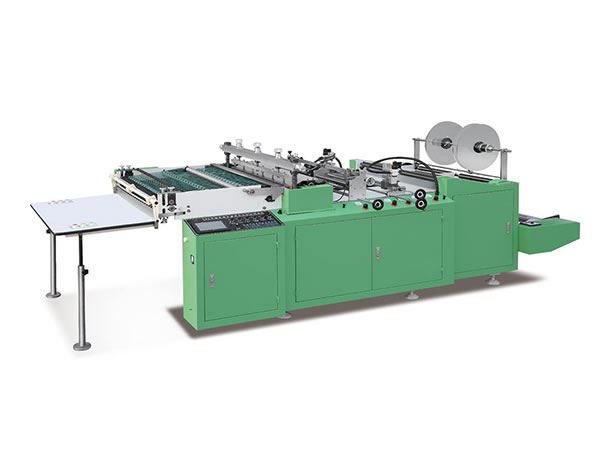

High Speed Paper Cup Forming Machine, JBZ-122D

The high speed paper cup forming machine JBZ-122D is newly developed based on the common paper cup making equipment. Through innovation and improvement, the overall performance and the production speed of the disposal paper cup production line has been greatly enhanced.

The production process includes automatic material feeding, cup body forming and sealing, cup rim lubricating, cup bottom punching, bottom paper positioning, bottom heating, rolling, cup rim curling, finished product conveying, etc. Our high speed paper cup forming machine is generally used for manufacturing ice cream cup, single or double PE coated paper cup for cold and hot drinks, and some others.

Features

- The whole steel plate fuselage, inter layer paper feeding design and the style of oil poured lubrication system is Ensured the equipment long-term normal and Stable Work

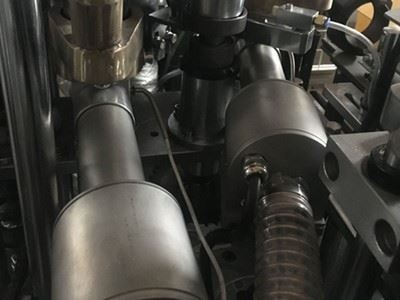

- Short distance double vertical axis combine advanced and high-precision cylinder open type cam drive make every stations high-speed worked accurate without mistake

- Single wrap the leaf groove cam structure combine seesaw roof bar design can make the high-speed paper feeding go to the place accurately

- Exquisite original creation ¢490mm mould turn plate design make the equipment work load more light and the speed to be more fast

- Scientific and reasonable mechanical is fit Itinerary design can using in premise of exchange mould can make the products producing range 6oz-16oz

Specification

| Model | JBZ-122D |

| Cup size | 6-16oz Top diameter: 60mm-90mm Bottom diameter: 40mm-70mm Cup height: 54-135mm Bottom depth: 5-10mm |

| Production capacity | 80-120pcs/min |

| Main motor power | 1.5kW |

| Total power | 16kW |

| Air source | 0.4m3/min, 0.5-0.8 MPa |

| Raw material | 160-350g/m2(Double or single side PE coated) |

| Weight | 2200kg |

| Dimension | 1900x1350x2000mm 1220x950x2080mm |